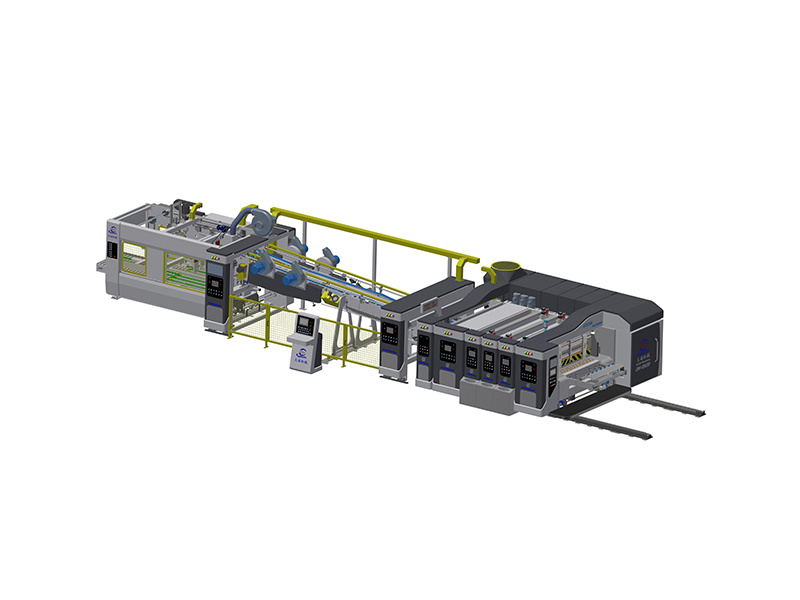

Fully vacuum adsorption corrugated carton box printing slotting die cutting machine(down print)

Product features:

◇ Move unit, upper adsorption, cardboard under the printing method.

◇ Can be directly connected with the corrugated board production line operation, eliminating the cardboard paper down the need to turn over the printing process.

◇ Directly with the flat pressure die cutting machine, automatic baler connection production, printing, lighting, flat pressure die cutting, binding and binding integrated linkage production.

◇ Direct with the folding automatic box machine, automatic box machine line production.

◇ It can be matched with grooving group, round pressure round die cutting group, waste cleaning machine, automatic stacking machine connection, so that the stacked paper stomping directly sent to the semi-automatic box machine, semi-automatic box bonding machine production, eliminating the traditional printing machine needs to turn the printing surface process.

◇ Optional pipe system: can connect the production management system, support remote access, control the execution of the machine, effectively integrate the existing resources of the enterprise, improve management efficiency.

Machine parameter

| Project | 0920 | 0924 | 1224 | 1228 | 1426 | 1628 |

| Max.speed (pcs/min | 260 | 220 | 220 | 200 | 180 | 160 |

| Feeding precision (mm) | ±1 | |||||

| Min.sheet size(mm) | 300×500 | 340×600 | 420×600 | |||

| Max.sheet size(mm | 860×2100 | 860×2500 | 1150×2500 | 1150×2900 | 1350×2700 | 1500×2900 |

| Skip sheet size (mm) | 1200×2100 | 1200×2500 | 1500×2500 | 1500×2900 | 1800×2700 | 2000×2900 |

| Max.printing area (mm) | 900×2000 | 900×2400 | 1200×2400 | 1200×2800 | 1400×2600 | 1600×2800 |

| Printing precision (mm) | ±0.5 | |||||

| Plate thickness (mm) | 7.2 | |||||

| Minimum slot distance (mm) positive knife(mm) |

130×130×130×130 | 140×140×140×140 | 150×150×150×150 | |||

| Minimum slot distance (mm) negative knife(mm) |

230×65×230×65 | 240×70×240×70 | 240×75×240×75 | |||

| Max.slot depth (mm) | 230 | 300 | 360 | 400 | ||

| Increase the blade,increase the slot depth | ||||||

| Slotting precision (mm) | ±1 | |||||

| Max.die cutting size(mm) | 900×1950 | 900×2400 | 1200×2400 | 1200×2800 | 1400×2600 | 1600×2800 |

| Die cutting precision (mm) | ±1 | |||||

Printing Sample

Detailed introduction

Paper Feeding Unit

◇ Servo motor independent drive, no gear clearance wear, long life, high precision.

◇ Vacuum adsorption front paper, frequency conversion control air volume, paper stable and accurate.

◇ Extension paper delivery system, according to the length of the cardboard, determine the paper delivery travel size, improve the accuracy of paper delivery.

◇ Pressure-free paper delivery system to avoid the destruction of the cardboard transmission process and ensure the compressive strength of the original cardboard.

◇ The whole machine automatic zero system, storage of common orders, quick order change, convenient operation.

◇ Widening dust removal device, in addition to electrostatic brush, can remove the cardboard surface dust, improve the printing quality.

◇ Left and right baffle, back support are computer control, precision guidance mechanism, smooth displacement, with side shot function.

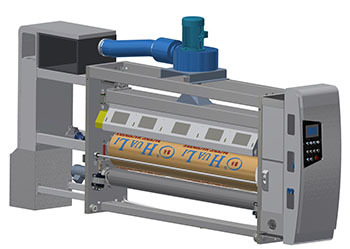

Printing unit

◇ Vacuum adsorption, ceramic wheel transfer, printing under the cardboard.

◇ Printing phase, version roller horizontal computer control.

◇ Electromagnetic braking mechanism, when the machine table separates or adjusts the phase, the braking mechanism limits the gear rotation, to maintain the original gear position fixed point.◇ Pneumatic double diaphragm pump, ink supply, stable circulation, simple operation and maintenance, ink filter screen, filter impurities, stainless steel ink tank.

◇ Quick replacement of rubber roller, net roller device, with quick replacement support.

◇ Automatic reset system after cleaning the printed plate.

◇ Optional: scraper, ceramic mesh roller uniform ink way.

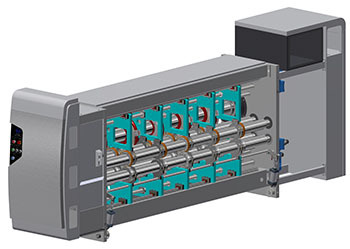

Slotting unit

◇ Slot knife wheel form: double knife single axis type.

◇ Alloy steel material after heat treatment and grinding of serrated slotted blade, with good hardness and toughness.

◇ Press line wheel, blade seat horizontal movement, phase adjustment, reset can be computer control (automatic or manual) electric control, replacement quickly.

◇ The upper and lower knife linkage, with the cutter into the slot positioning function, to ensure that the knife seat left and right adjustment and synchronous movement, separate the lower blade, convenient maintenance and replacement, and prolong the life of the cutter.

◇ Prepress transmission, the surface of the prepress wheel wrapped with Excellent glue, to avoid damage to the cardboard.

◇ The pressing wheel embedded in the excellent glue, the transverse position of the pressing wheel can be adjusted with the slotted knife seat.

◇ Middle knife lateral displacement structure, wide production adaptability.

◇ Elastic Angle cutting knife structure, three layers, five layers of cardboard cut Angle without adjustment.(Patent technology)

◇ Precision linear guide rail, with the ball screw, makes the slotted knife holder move more flexible and accurate.

◇ Optional: double-knife and double-axis slot unit.

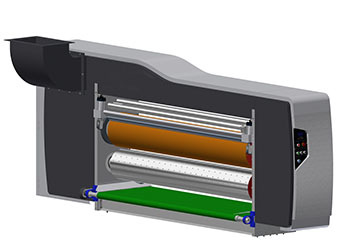

Die-cutting unit

◇ Equipped with imported quick change polyurethane felt sleeve, easy to replace, with one-way clutch as line speed compensation function, can ensure that the mold cut after the felt wear is completely the same.

◇ Working die-cut felt sleeve drum mechanical spiral left and right automatic transverse movement (± 20mm), so that the incision knife mark is not repeated, prolong the service life of the felt sleeve.

◇ The gap between the felt roller and the die-cut roll is controlled pneumatically. When the felt roller drops to the working position, and the felt roller rises automatically rise when the feeding is stopped.

◇ Felt sleeve correction mechanism, increase the number of rubber pad use, reduce consumption.

◇ The bottom of the die cutting is equipped with waste paper conveying device, the paper scraps to the equipment, convenient cleaning.

◇ Optional: die-cut rubber pad roller servo independent drive system.

Company profile

OCEAN CARTON MACHINETRY is located in Dongguang County, Hebei Province, we are an intelligent supplier with professional of carton packing research development and production, we are a modern enterprise with integrating design,R&D, production, sales and after-sales, Our production have a reputation for timely delivery ,good service to win the user’s highpraise.ln the future, we will take the market-oriented, science and technology development as main power, sincerely cooperate with the users, constantly updated products, continuously improve the quality of product, perfect after-sales service,sincerelyreturn society.Our company's products are designed and manufactured accordingto European standards. The equipment is exported to more than 60 countries, and more than 20 provinces in China.Many places havesales office and after-sales outlets to provide customers with guarantee services.

Professional team

Our Commitment to Providing Our Customers with Best Services.

★ Our sales team has professional product knowledge and rich application experience. They are optimistic and enthusiastic and provide you with the most thoughtful service.

★ Whenever you have questions about our products after receiving the goods, our after-sales services team will answer your questions patiently and solve your problem promptly.

Certificate

Company exhibition

Ocean Machinery focuses on developing the most cost-effective carton packaging machines, in order to meet customers increasing demands. We provides packaging solutions throughout the world. More than 150 machines have been installed in 50+ countries all over the world, like Japan, America, UK, India, and so on. Both machine performance and customer service have received tons of excellent reviews from our partners and customers.

FAQs

Q: Are you trading company or manufacturer?

A: We are manufacturer, and also provide the business solution to all the friends.

Q: Do you have quality certificate?

A: Yes we have CE, etc.

Q: What's the delivery time?

A: Around 20~30days, however, based on order.

Q: Can you help us to buy other goods?

A: Sure of that, it is our honor to work for you, and control the goods quality.

Q: What's payment terms, trade terms you accept?

A: Usually we appreciate T/T 30% deposit, then 70% balance is paid before shipment , we usually offer FOB tianjin price. but we also accept other way like L/C, wetern union, and do CFR&CIF etc.

Q: Does it easy to operate and what can i do if it doesn't work?

A: We suggest you to come to visit our factory to learn more thing by yourself, and if there is something goes wrong , you can call us, video-chat, email us. And we will give solutions within 36 hrs. Our engineer also can be distributed to overseas as you required.

TAG:

Fully vacuum adsorption corrugated carton box printing slotting die cutting machine(down print)

Category: